-

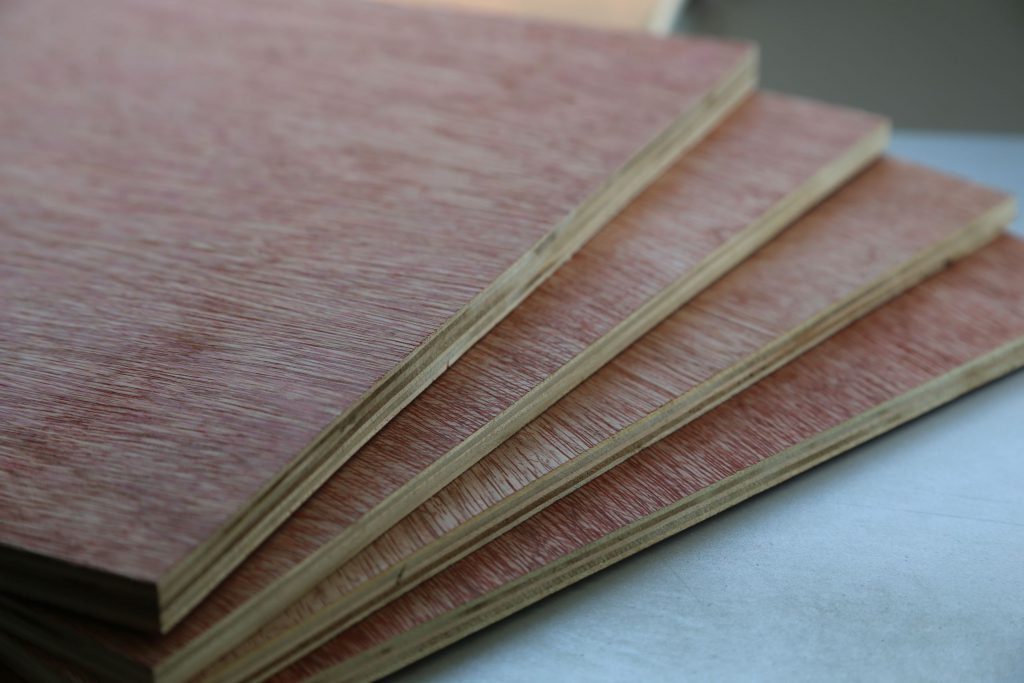

Vietnam Film Faced Plywood Information

Vietnam film-faced plywood also known as film-coated plywood, water-resistant plywood is a type of plywood which made by pressing all the ply of wood (veneer) together using 100% WBP – Phenolic water-resistant special glue by hot pressing method at a temperature of 125 – 140 degrees Celsius, with the surface covered with 2-sided Stora enso film which gives the board a smooth, glossy, scratch-resistant finish appropriate for use in construction.

2.Film-faced plywood specifications

Type: Both filmfaced, single-filmfaced, tego plywood

Size: 1220 x 2440 mm – 1250 x 2500 or customized

Face/Back: Plain Black/Brown Film, Logo Film

Core: Mixed hardwood (acacia, eucalyptus, styrax)

Hot pressing: 2 times

Core sanding: Yes

Tolerance: ± 0.3 – 0.5mm

Glue Type: WBP (Melamine)

Thickness: 12 – 15 – 18 – 21 (mm)

Maximum moisture: 10%

3. Advantages And Disadvantages Of Film Faced Plywood

3.1 Advantages Of Film Faced Plywood

– The film is a thin plastic film that prevents water absorption with a flat surface that reduces scratches and can be reused many times.Thus, it not only brings efficiency to the project, but also ensures a lot of cost savings.

– The weight of Vietnam film faced plywood is relatively light, so it is easy to move, load, unload, construct and install in the construction site.

– The surface of the board uses mixed wood, which is the perennial hardwood tree in the forest, the density is quite high, the wood veneers are of good quality, often used as a faceboard, high durability, little scratches and easy cleaning wipe.

– Vietnam film faced plywood has the ability to withstand large external forces, ensuring safety when executing construction works and installing easily thanks to the characteristics of easy sawing, splitting, and good adhesion.

3.2 Disadvantages Of Film Faced Plywood

The disadvantage of Vietnam film faced plywood is that it is more expensive than other types of plywood and requires proper installation and construction to ensure the best quality for the project.

4. Product Application

Vietnam film faced plywood is mainly used to make formwork in construction, due to its high water resistance and durability.

– Low cost, no maintenance costs. Simple and easy to replace

-The formwork board has high elasticity and anti-warping.

– The area of each sheet is large with high uniformity, creating outstanding advantages when constructing a large floor area