Briquette charcoal is made of sawdust is really valuable products because of it’s uses and environmentally friendly function. Making the charcoal from sawdust is considered as a good fuel source for both industrial and residential. It is one of the preferred BBQ charcoal because it is smokeless and odor free. It has a long-lasting energy effect and can be used in industries making metals such as steel.

How to Make Charcoal Briquettes from Saw Dust?

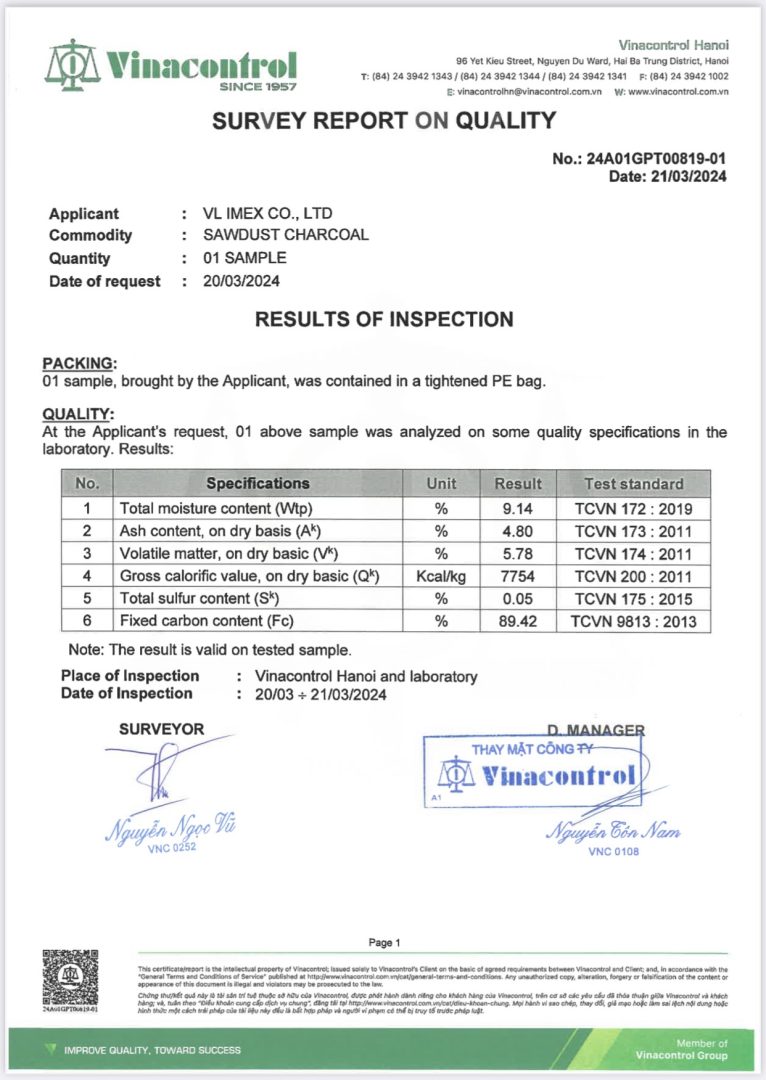

The raw materials to make sawdust charcoal briquette is saw dust. In order to guarantee a larger productivity, the saw dust be below 1cm in size and the moisture content should be less than 12%. to guarantee a larger productivity.

- First, pass the sawdust into a crusher to crush them into about 5-millimeter size. Then pass the crushed materials through a large drum dryer to reduce its moisture content. It should be dried to a moisture content of between 8 to 12 percent. Once you have the materials dried, feed the sawdust into the biomass briquette machine by pressing it inside the machine.

- Compress the Biomass briquette machine under high pressure and temperatures in a process known as briquetting. During this process there is self-bonding which involves thermoplastic flow of the biomass. Lignin content is formed naturally inside the biomass machine due to high pressure and temperatures, and it is liberated. It serves as glue, binding and compressing the biomass to form high-density briquettes.

- While inside the screw briquette machine, the materials being briquetted are stirred by a center shaft inside the machine to ensure a uniform combustion. Once the biomass has been briquetted, they are placed into the carbonization furnace. This will carbonize them to the machine made charcoal briquette. In the carbonization furnace, minor ingredients such as starch binder are included where they are blended together with the materials.After blending, drop the material into a press machine that makes them into sizes. It is then taken to a conveyor machine where the material is heated under high temperatures to reduce its moisture content to less than 5 %. The charcoal briquettes are ready and can be stored. The charcoal will be of high density and a high heat value. Furthermore, just like the natural charcoal, it will be smokeless and odor free. The charcoal briquette is an environmental friendly product because it does not pollute the environment.